Barcode scan system of two head stitching machine

As we know most of us will make some mistakes during our working, but we can adopt some efficient preventive steps, such as fool-proofing according to machine, double checked etc.

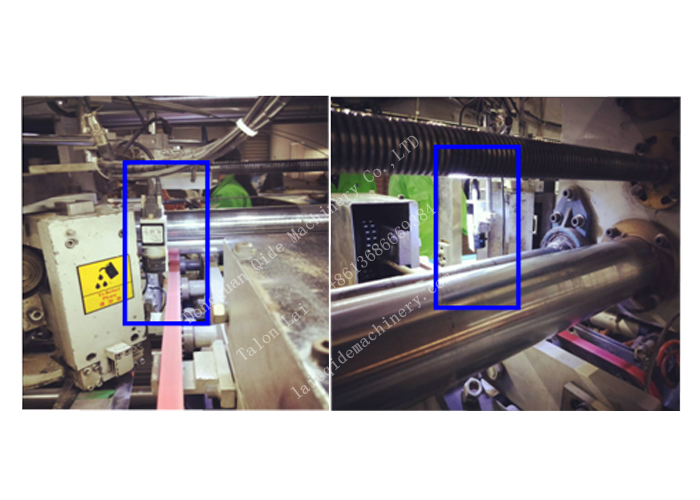

So at the same time we can add barcode scan system in our double head stitching machine, which was adopted with high speed barcode scan system, prevent sheet A stitching wrongly with sheet B of similar serious products in our customers.

How is barcode scan system working?

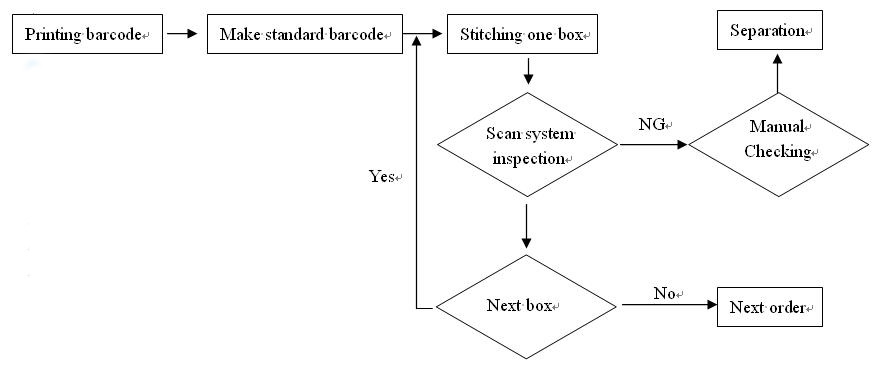

1. We will require customers print two different barcode in corrugated sheet.

2.Make a standard sample in scan system, set barcode of sheet A in barcode scan system, set barcode of sheet B in barcode scan system.

3. Operators feed cardboard into baffle of two head joint stitcher, scan system will be automatic scanned barcode, and machine will be stop working once sheet A is same as what we set in scan system (Standard sample), at the same time system will be showed NG in screen; if sheet A is different with sheet B, two head stitching machine will be auto stitching box, while it is showed OK in screen.

4. Stitching next box.

Let’s see how it works in flow chart.

What do we need for barcode scan system?

1. Scan guns/2pcs;

2. Display/1pcs;

3. Two head stitching machine/1pcs

4. Barcode in sheet A and sheet B.

What are advantages of our barcode system?

1. Labor saving, fool-proofing, and protect our workers health;

2. Gurantee quality for customers, without mixing products and customer complaint;

3. Easy operating, LCD screen;

4. Inspected damaged and unclear barcode defective products.

Your choice our best - Two head stitching machine of barcode scan system