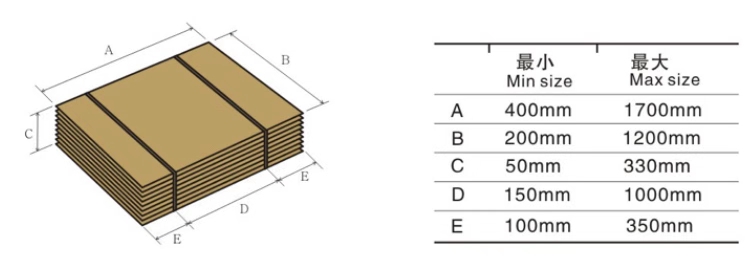

Fully auto tying machine inline FFG

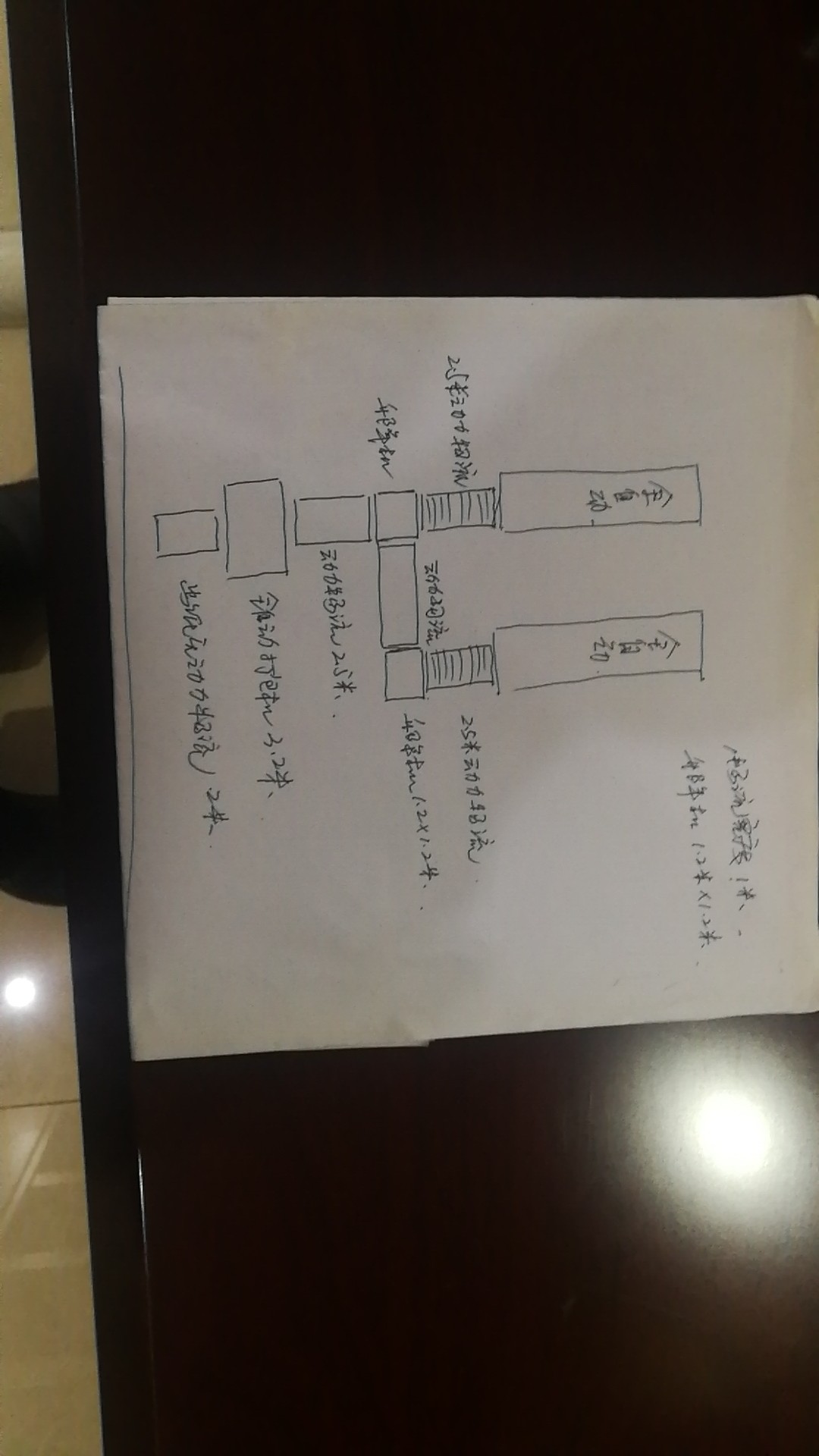

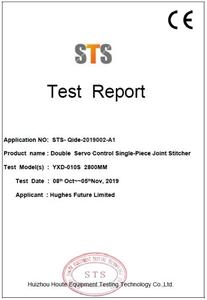

1 Adopted double servo, double press, double push, double open structure, applied for corrugated cardboard and boxes

2 Strapped single and double tie packaging

3 Feeding unit and front rack adopted mounting bracket, back rack adopted double open single press, which will be increased packaging speed and steady,

4 Low cost: The cost of PE belt was 3-5 times lower than the PP belt

5 Good stability: Imported servo control system helps to reduce the mechanical drive and Mechanical wear, expand the lifespan

6 Humanization design: automatic counting and production yield

7 Multifunction HMI, easy to operate, imported programmable fault monitoring system

8 Left and right head can be adjusted independently, easily and versatile operating

9 Finishing tie is more feasible, when knotting it will be far away from machine for preventing box damaged.

10 Used Schneider electric brand( Servo, switches, proximity switch, limit switch, contactors); all packaging sizes are set by computer; SMC pneumatic flutter made products look neat artistic

11 Conveyor belt are imported from Italy

Fully auto PE strapping machine YH 020 1700mm