- Home

- >

- Products

- >

- Two Piece Joint Stitcher

- >

- TV box stitching machine

TV box stitching machine

Brand :Qide

Product origin :China

Delivery time :20-30days

Supply capacity :20sets/month

TV box stitching machine

Double Servo Control - Japan Yaskawa

Used Mitsubishi PLC,and PLC program is wrotten by ourselves,

Our got patents in 2007 for box stitching machine,

TV box stitching machine

1.Double Servo Control - Japan Yaskawa

2.Used Mitsubishi PLC,and PLC program is wrotten by ourselves,

3.Our got patents in 2007 for box stitching machine,

4.It takes 3-6 minutes to shift orders,

5.Stitching distance can be 15-120mm,adjustable,

6.Machine speed:500nails/minute,

7.20Kg auto big wire feeder,

8.Stitching nails no.:1-99nails,

9.Auto counter ejector, any packs no. can be setted in touch screen,

10.Very easy operation no tranning required,

11.Single, double and tie stitching are available, all the nails can be rounded off in one time

12.Suitable for boxes with cover or without cover

13.Rear baffle was Electrically controlled,

14.Single piece ,two piece are doable for one machine,

15.Professional service team,and online service,

16.English,Vietnamese,Thail and any other language can be showed in control panel.

DongGuan QiDe Machinery Co., Ltd XinNan 2nd Industrial Zone, Qi Shi Town, Dong Guan City, Guang Dong Province, China | ||||||||

| Talon lai Pho:+8613686669384 Tel:86 769 86666261 Email:lai@qidemachinery.com | ||||||||

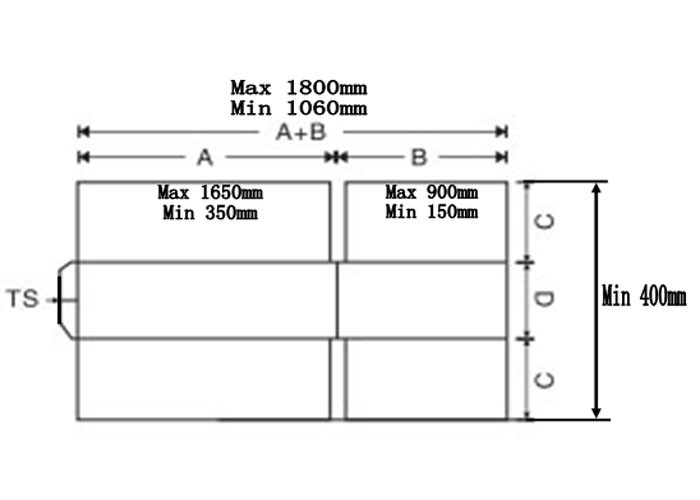

YXD-040 1800mm Double Servo Control Twin Head Semi Auto Stitcher (Special Equipment for Color carton,TV box ) | ||||||||

| Specification | YXD-040 | |||||||

| 1800mm | ||||||||

| Max.Sheet size(A+B)×2 | 3600mm | 141.7inch | ||||||

| Min.Sheet size(A+B)×2 | 1060mm | 41.7inch | ||||||

| Max.Box Length (A) | 1650mm | 65inch | ||||||

| Min. Box Length (A) | 350mm | 13.7inch | ||||||

| Max. Box Width (B) | 900mm | 35.4inch | ||||||

| Min. Box Width (B) | 150mm | 5.9inch | ||||||

| Min. Sheet Height (C+D+C) | 400mm | 15.7inch | ||||||

| Max. Stopper Measurement(C) | 600mm | |||||||

| Max. TS Width (TS) | 45mm | |||||||

| Min the first stitching position | 25mm | |||||||

| Cardboard thickness | 8-13mm | |||||||

| Stitching Pitch | 30-120mm | |||||||

| No. of stitching | 1-99 Stitches or more | |||||||

| Machine Speed | 500 Stitches/Minute | |||||||

| Power Required | 10 HP | |||||||

| Input Voltage | 380V three phase | |||||||

| Stitching wire(width*Thickness) | (0.68-0.75)*(1.8-2.0)mm | |||||||

| Stitching wire tray | 5KG | |||||||

| Machine Length | 4000mm | |||||||

| Machine Width | 3400mm | |||||||

| Machine Weight | 4000KG | |||||||

| Stitching Type | Single, Double, Tie Stitching:"/ / / / /" 、 "// // //" 、 "// / / / //" | |||||||

| Twin Head Semi Auto Stitcher Main accessories: | ||||||||

| Description | Brand | |||||||

| Stitching head | Taiwan XX | |||||||

| Servo Control System | Japan Yaskawa | |||||||

| PLC | Japan Mitsubishi | |||||||

| Touch Screen | Taiwan Weilun | |||||||

| Twin Head Semi Auto Stitcher Machine parts | ||||||||

| No | Name | QTY | www.qidemachinery.com | |||||

| 1 | Main machine | 1PCS | ||||||

| 2 | counter ejector | 1PCS | ||||||

| 3 | conveyor roll | 1PCS | ||||||

TV box stitching machine

TV box stitching machine

Twin Head Semi Auto Stitcher

Packaging and Transport: Steel pallet, package with carton & shrink wrapped

1) Standard packing for Twin Head Semi Auto Stitcher .

2) Customer need prepare power, air pressure and layout for running the machine.

3) Most required components for installing machine will be provided for free.

4) After machine is shipped to you, if necessary our engineer will go to your site to help installation and training for free, but you need pay round trip tickets and accommodation.

Our Services

1) MOQ: One set- Twin Head Semi Auto Stitcher

2) Customized machine--We can produce as client's demand

3) High Quality: Machines will be strictly 100% inspected by quality control department. Good reputation on the market.

4) Fast and sincerely service delivery: 7*18H on line service.WhatsApp +8613686669384.

5) Processional Design, Self design, efficient.

6) Easy operation.

7) Reasonable price.

Your cares

1) Inquiry professional quotation-Twin Head Semi Auto Stitcher

2) Confirm the price, lead time, payment term etc.

3) Sales send the Proforma Invoice with company seal.

4) Customer makes payment for deposit and sends us Bank Receipt.

5) During Production- We will send photos and videos to show the production line which you can see your products.

Cooperation and double win

1) Clients make payment for balance before shipment.

2) When machine is running well and satisfied, please fill in our installation acceptance report.

3) Please feedback to us about quality, service, market and any suggestion to be better ourselves.

Your choice our best! 2 Piece Stitching Machine